How to pressurise boiler with low water pressure – A Comprehensive Guide for Homeowners With Low boiler pressure

Even though we recommend getting professional assistance from one our Gas safe registered and expert London based Engineers for any boiler issues It is important for homeowners to know how to re-pressurize their Boilers. This comprehensive guide will provide step-by-step instructions on how to re-pressurize a boiler. It will also discuss the importance of maintaining the correct pressure in order to keep your boiler running safely and efficiently.

how do you determine whether your boiler’s water pressure is low?

observe the pressure gauge to ensure it is not in the red. The ideal pressure is around 1.5 bar

Boiler water pressure is an important factor to monitor with your home heating system. If the pressure is too low, you may experience reduced heat output and even a complete boiler shutdown, usually accompanied by an error code.

Fortunately, there are simple ways you can check your boiler’s water pressure to ensure that it is at the optimal level. In this article, we will discuss how to determine whether your boiler’s water pressure is low and what steps you can take to fix the issue.

What causes a boiler pressure to drop?

A variety of factors ranging from, The bleeding of radiators, A leak somewhere on the central heating system and a boiler leak/ faulty part can cause A drop in boiler pressure.

Bleeding radiators

Bleeding radiators are a common maintenance task in central heating systems. This procedure involves releasing any trapped air in the radiator, which improves system efficiency. However, bleeding radiators can result in a decrease in boiler water pressure.

The pressure in the heating system is critical for ensuring that hot water is circulated efficiently throughout the property. When air is released from the radiator, pressure is also released, which causes a pressure drop. This drop in pressure can result in a variety of problems, such as a lack of hot water, cold radiators, or even a complete Boiler lockdown.

A leak somewhere on the central heating system

If there is a leak, water will escape from the heating system, causing a loss of pressure. As a result, the boiler will struggle to maintain the required water pressure, which can cause several issues.

To identify if there is a leak in the system, homeowners can check for damp patches, pooling water, or any unusual hissing sounds near the pipes or radiators. If you suspect there is a leak in the system, it is essential to address the issue promptly to prevent any further damage to the heating system or property.

Please not if this is the cause fixing a leak in the heating system should always be carried out by a qualified engineer to ensure the repair is done correctly and safely. They will need to identify the source of the leak and carry out the necessary repairs, which if this was the sole cause should restore the water pressure to the boiler.

Internal boiler leak/ faulty part

Leakage from within the boiler can arise when internal components corrode or loosen over time. Without regular servicing, the wear and tear can cause a loss of pressure in the system, often resulting in visible dripping from the underside of the boiler. If you suspect a leak with the boiler itself, it is essential to seek the services of a respectable Gas Safe Registered engineer to inspect the boiler. It is important to note that the boiler casing should not be removed by an untrained individual.

After inspection, the engineer will advise on whether the affected part can be repaired or replaced. They may also recommend a cleaning or replacement of the entire system. Homeowners should check the warranty of their boiler, as it could potentially save them a significant amount of money on repair costs.

In addition to leaks, faulty parts can also cause heating problems in boilers over time. To identify and address faulty parts, it is essential to consult a Gas safe registered engineer. Attempting to identify and repair the fault by oneself can result in further damage to the system and potential safety hazards. Once identified, the engineer will advise on the necessary repairs or replacements needed to restore the boiler’s optimal functioning.

ways to repressurise your boiler’s pressure

Repressurizing a boiler can be done in various ways dependent on the design of your boiler.

Built in filling loop

External filling loop

Internal filling key

Here’s how to use these 3 methods:

Re pressurising your boiler with a built in filling loop

- Turn off the boiler and heating system.

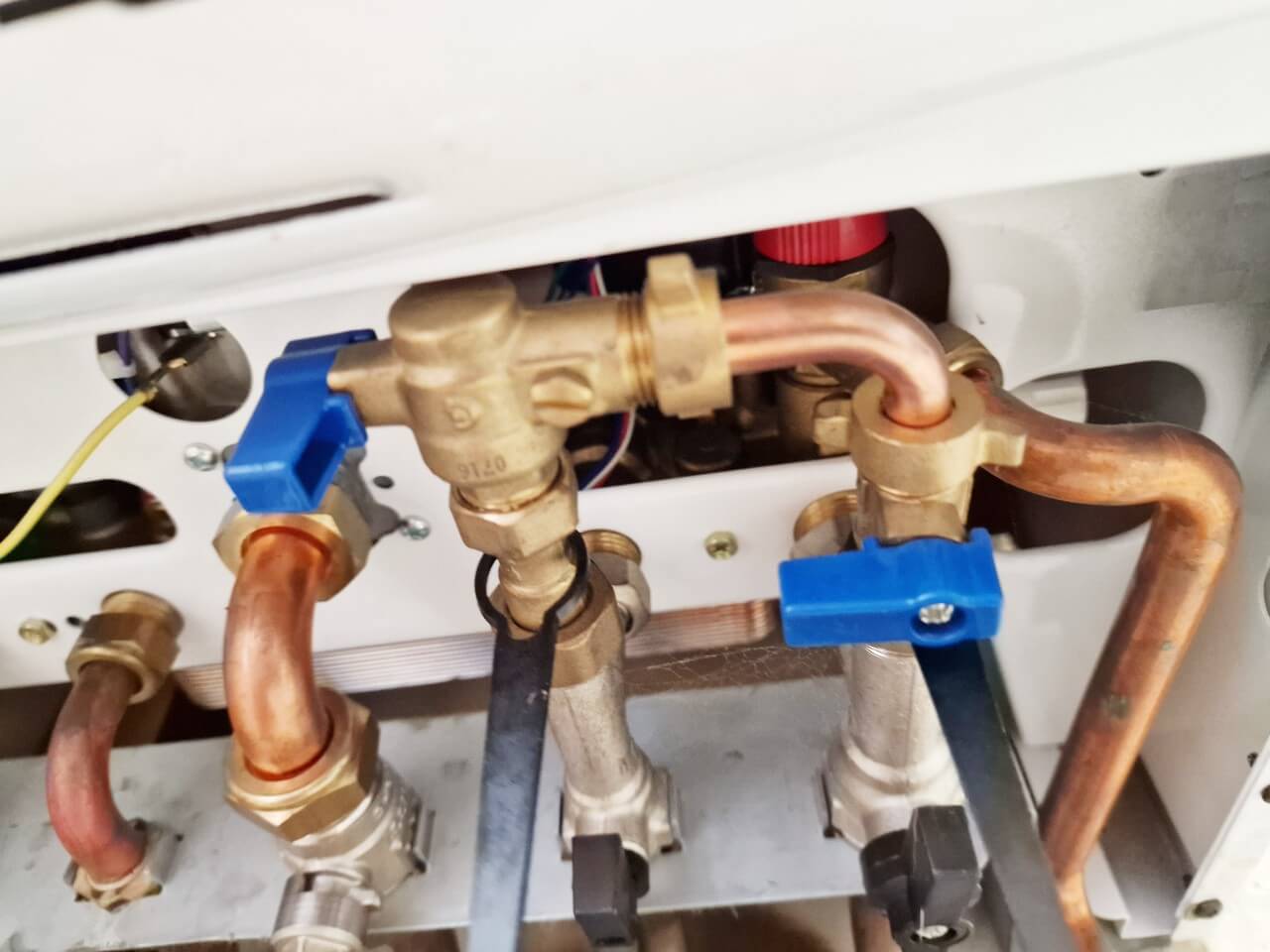

- Locate the built-in filling loop, which is typically a lever or a valve on the underside of the boiler.

- Open the valve or flip the lever to allow water to flow into the system.

- Watch the pressure gauge on the boiler and close the valve or lever once the pressure reaches the desired level, typically between 1 and 1.5 bar.

- Turn the boiler and heating system back on and check that everything is working correctly.

Repressurising your boiler with a external filling loop

- Turn off the boiler and heating system.

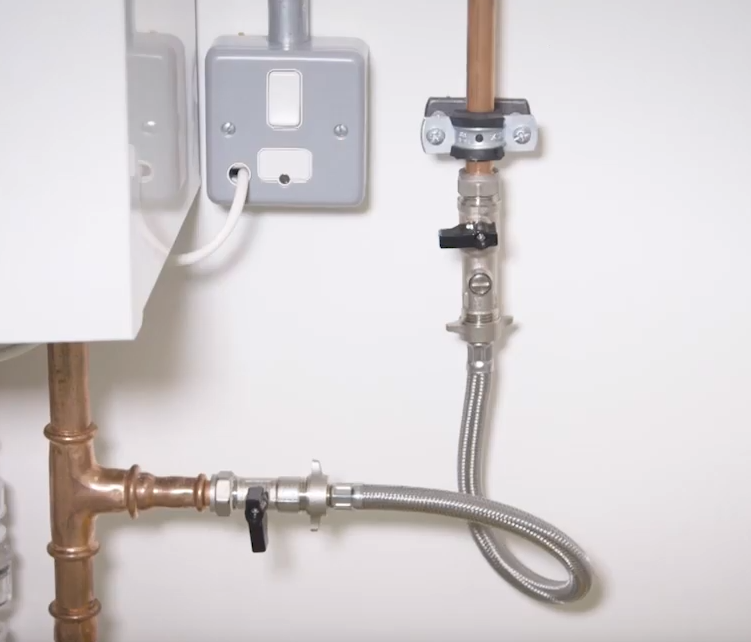

- Locate the filling loop, which is usually a flexible metal hose that is connected to the boiler at one end and to the water supply at the other end.

- Open both valves on the filling loop to allow water to flow into the system.

- Watch the pressure gauge on the boiler and close the valves on the filling loop once the pressure reaches the desired level, typically between 1 and 1.5 bar.

- Turn the boiler and heating system back on and check that everything is working correctly.

Repressurising your boiler with an internal filling key

- Turn off the boiler and heating system.

- Locate the internal filling key, which is usually stored near the boiler.

- Insert the filling key into the valve located on the underside of the boiler.

- Slowly open the valve on the filling loop that is connected to the cold water supply, and you should hear the sound of the water filling the system.

- Watch the pressure gauge on the boiler and close the valve on the filling loop once the pressure reaches the desired level, typically between 1 and 1.5 bar.

- Remove the filling key from the valve and make sure that there are no leaks in the system.

- Turn the boiler and heating system back on and check that everything is working correctly.

Step 7: Checking the Water Pressure Gauge

It’s time to check your pressure gauge again after completing the previously mentioned processes. You’ve almost addressed that problem if the boiler successfully hits 1.5 bars. What’s left for you to do is to…

What Is The Best Central Heating System

There is no definitive answer to this question and is a matter of preference there are a range of options on the market today but by far the most used form of heating in the u.k are gas central heating systems, They are constantly evolving and being refined and today most gas central heating systems operate at around 90% efficiency, which is a remarkable improvement compared to their predecessors.

Conclusion

Low boiler pressure it’s a sign that something may not be quite right and you need to re pressurise your boiler. Pressure drop is mostly caused by bleeding radiators, leaks and other boiler faults, so it’s important always to double-check your pressure gauges to see if you need to re-pressurise boiler pressure not.

If your boiler is leaking, try getting damp patches to avoid loss of hot water.

There are different types of boilers (for example, a Combi boiler vs system boiler), and they all come with different pressure gauges, some have a digital gauge, so it’s important to study your gauge so you know there’s no longer any hot water and its time to re pressurise.

Help is a call away

if you have followed all the filling loop tips and your boiler still has problems, and the water is still leaking, then it’s time to call 02086112591 for one our expert gas safe registered engineers.